The system of unlimited possibilities!

The AFP®-modular system of LEANTECHNIK !

Universal accessory mounting

Extremly tight operating parameters

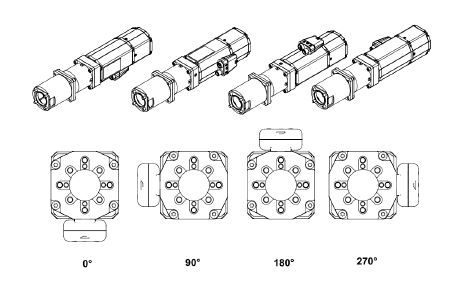

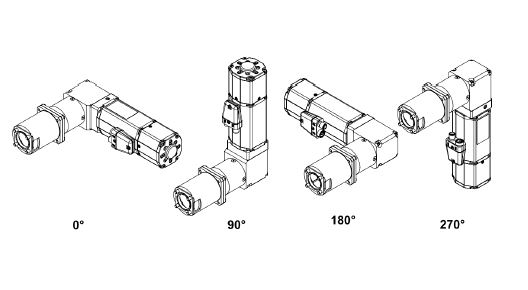

Freely selectable drive position

Highest precision

Simple & Quick installation

See our AFP® – modular system in action!

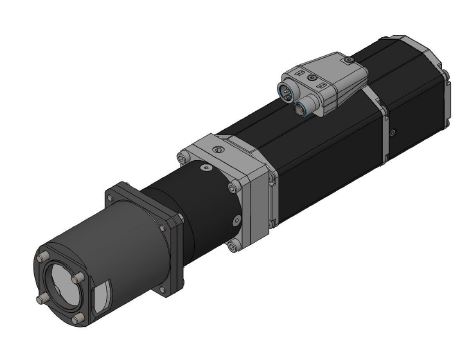

AFP® – Actuator Flexible Position

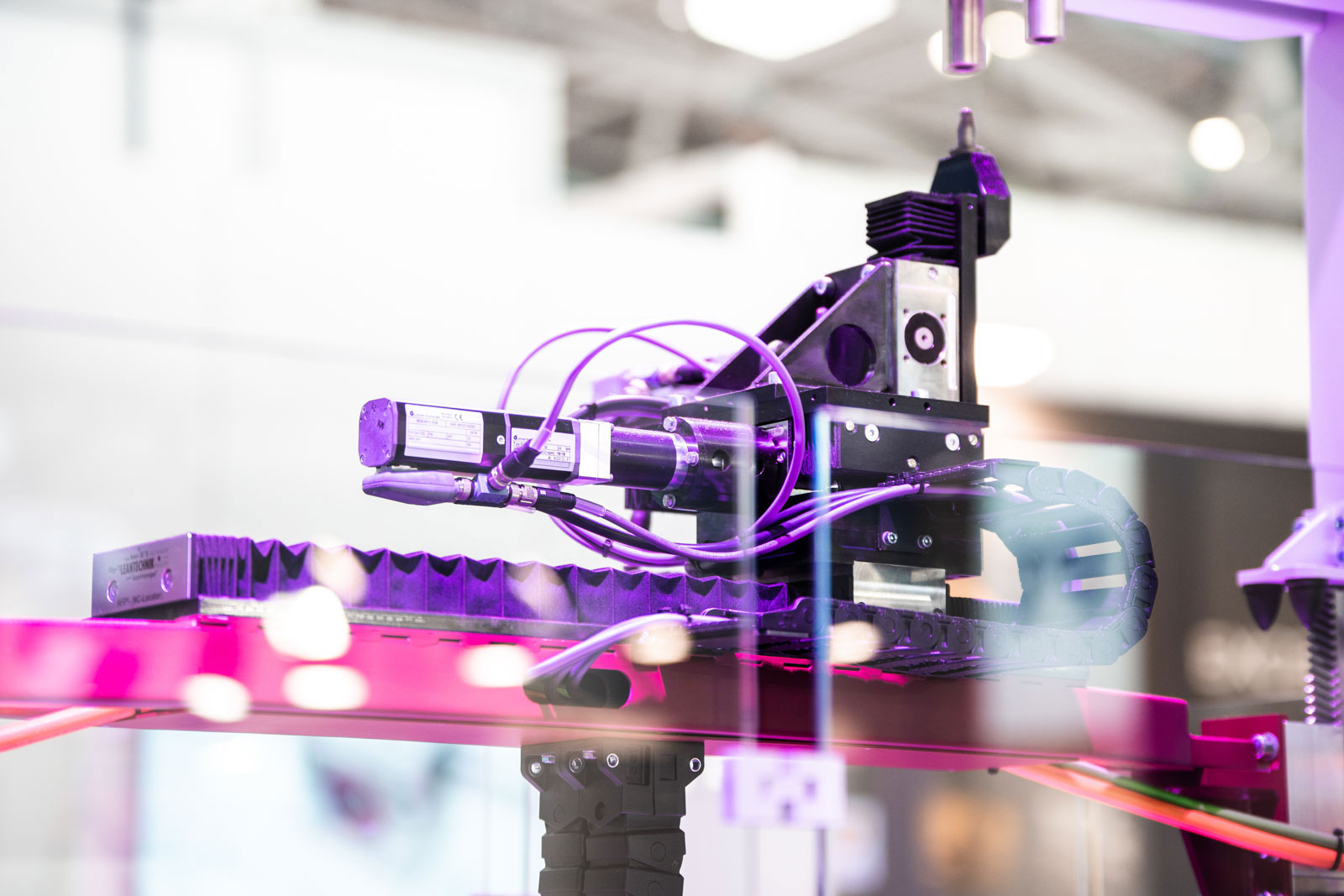

For numerous industrial manufacturers, production costs continue to rise due to increasing number of product classifications and declining lot sizes. With the new AFP – Axis’s from Leantechnik, there is a break through from this vicious cycle; offering the opportunity to produce numerous product variations economically on one line.

The NC locators are used to position brackets, clamps, or to centralize, as well as the flexible incorporation of product components. The AFP System consists of an X axis, Y axis and a Z axis; each with a 24 V brushless DC Servo drive that contains an easily integrated programmable control and a CANBUS interface. Each axis and motor drive are defined according to the specifications of the customer and are combined according to the requirements of the application.

The system was developed on behalf of a distinguished automotive manufacturer that wanted to reorganize the fabrication of its chassis within the assembly process. A single production line ought to have the ability to produce different automotive models without having to rebuild the production line each time. To optimally meet these conditions, Leantechnik has conceptually designed the NC-Locator modules as a “System Assembly Kit”. It is composed of individual axis’s, motor drives and connectors, which can be assembled collectively to achieve designated parameters. This creates a completely individual positioning system that incorporates flexibility for changing production conditions.

Each axis and every motor drive are defined separately and combined according to the customer’s assembly specifications.

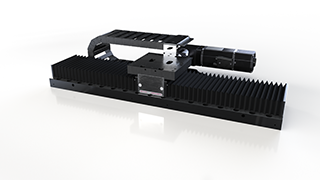

As the basis of the AFP®/NC Locators, we apply our proven lifgo® linear 5.0 Gear Rack Drives.

The transfer of rotary forces into linear motion, provides a lifting force of 2,000 newtons with a lifting speed of 3 m/s and an acceleration of 50 m/s².

The lifgo® linear series is characterized by its precise synchronization, even at high speeds and was specially designed for applications with long traverses.

The AFP® – modular system of LEANTECHNIK consists of:

X-Axis

(Longitudinal Axis)

Y-Axis

(Lateral Axis)

Z-Axis

(Lifting Axis)

+ Drive unit

In the modular system, the axes can be combined and used individually:

One-Axis-System

Two-Axis-System

Three-Axis-System

Strokes in our AFP® – modular system

X-Axis

150 mm

300 mm

400 mm

Y-Axis

90 mm

180mm

Z-Axis

90 mm

In the „light“-variant with the stroke paths: 60 mm, 150 mm, 300 mm, 400 mm

In the „single“-variant with the stroke paths: 150 mm, 300 mm

More information can be found in our Technical Data.

Lifting speed of the drive units in the AFP® – modular system

Drive unit straight

90 mm/s

Drive unit angle

90 mm/s

You need more technical data for our AFP® - modular system?

They are prepared to assist with design and development recommendations of cutting-edge solutions that meet your demands and requirements.

Check out our leantranspo® projects and find further information in our full catalogue.

You want to know more about our AFP® – modular system?!

Our sales team will be happy to advise you!

Our field service representatives are available anytime for a non-binding consultation at your facility. To contact your local representative, check who is responsible for your area.

While our product development and design departments are located at our Oberhausen location, our field service representatives are available to assist you anywhere in the US.

Headquarters:

![]() USA

USA

LEANTECHNIK LP

2220 Northmont Parkway,

Suite 250

DULUTH GA 30096

UNITED STATES OF AMERICA

E-Mail: info@leantechnik.us

Phone: +1 770 295 2286

Web: www.leantechnik.us

![]() USA – Michigan, Indiana, Illinois

USA – Michigan, Indiana, Illinois

Morrell Group, Inc.

3333 Bald Mountain Road

Auburn Hills, MI 48326

UNITED STATES OF AMERICA

E-Mail: sstearn@morrellinc.com

Phone: +1 248 373 1600

Web: www.morrell-group.com

![]() USA – Ohio, Kentucky

USA – Ohio, Kentucky

Hydrotech, Inc.

10052 Commerce Park Drive

Cincinnati, OH 45246-1388

UNITED STATES OF AMERICA

E-Mail:dschaefer@hydrotech.com

Phone: +15138817000

Web: www.hydrotech.com

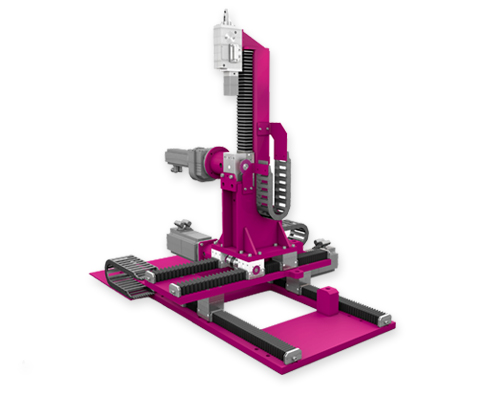

leantranspo® – Cutting Edge Solution

from the House of LEANTECHNIK

The development and construction of an individual leantranspo®-system integrates Gear Rack Drives – lifgo® and lean SL®, with parts, motors and steel frame structure. Individual leantranspo®-systems can be created for the most discriminate lifting applications.

leantranspo® is significant in the development and manufacture of parts and production systems.

• Lifting Tables and Lifting Columns

• Press Transfer Lines

• Pick and Place Systems

• Two and Three Axis Portals and Positioning Systems

• Lift & Lower Conveyor Systems

Benefit from our experienced engineering team. They are prepared to assist with design and development recommendations of cutting-edge solutions that meet your demands and requirements.