Stay FLEXIBLE with LEANTECHNIK!

Discover our Three-Axis-Positioning-System (DAP)

Flexibility

Tight Operating Parameters

Low Maintenance

Highest Precision

Simple Installation

Efficiency Enhancement

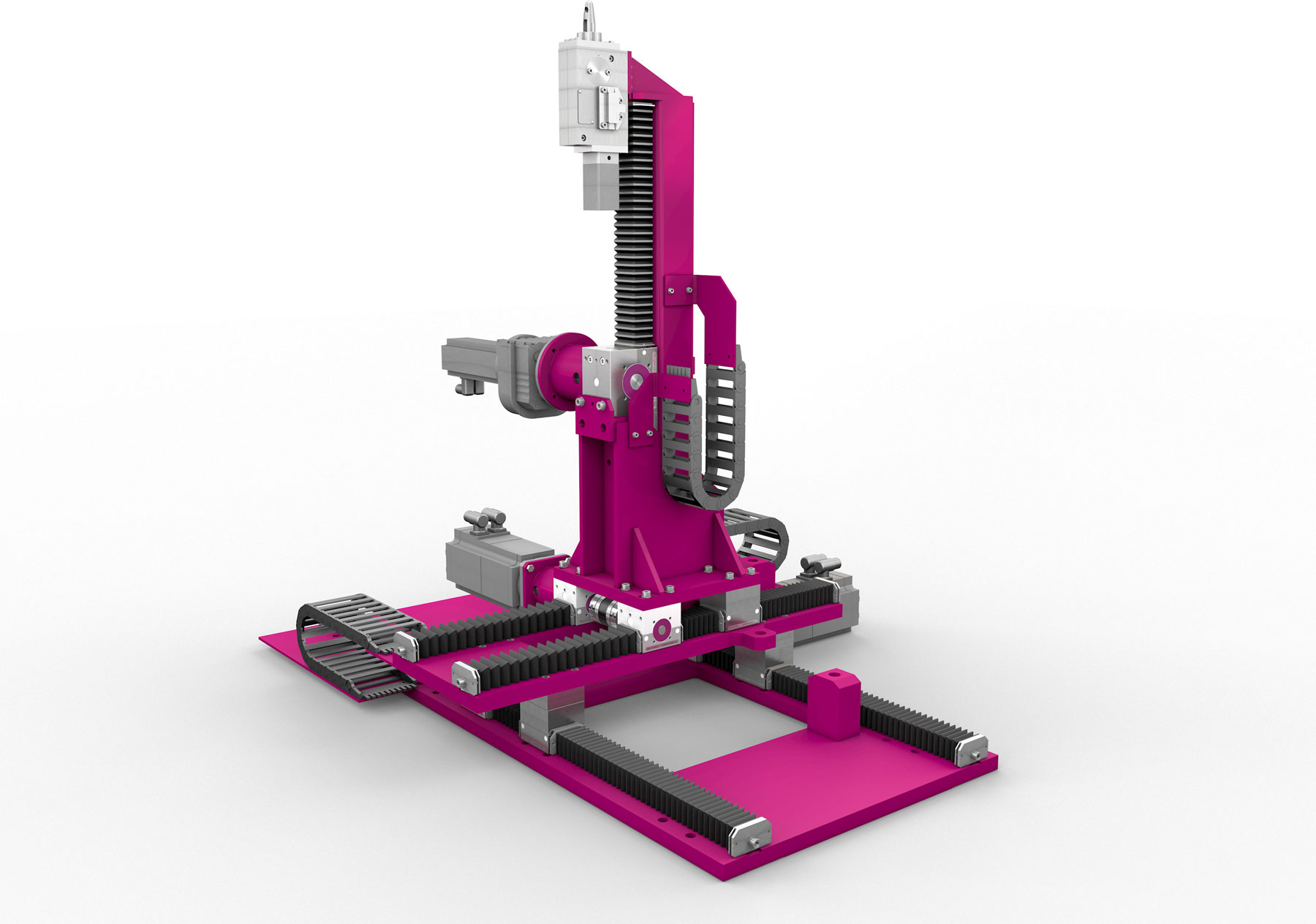

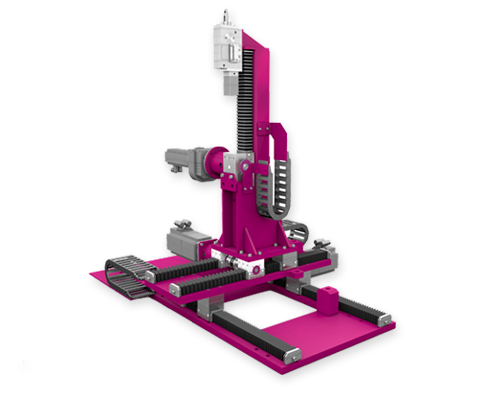

Three-Axis-Positioning-System (DAP)

Highest Flexibility

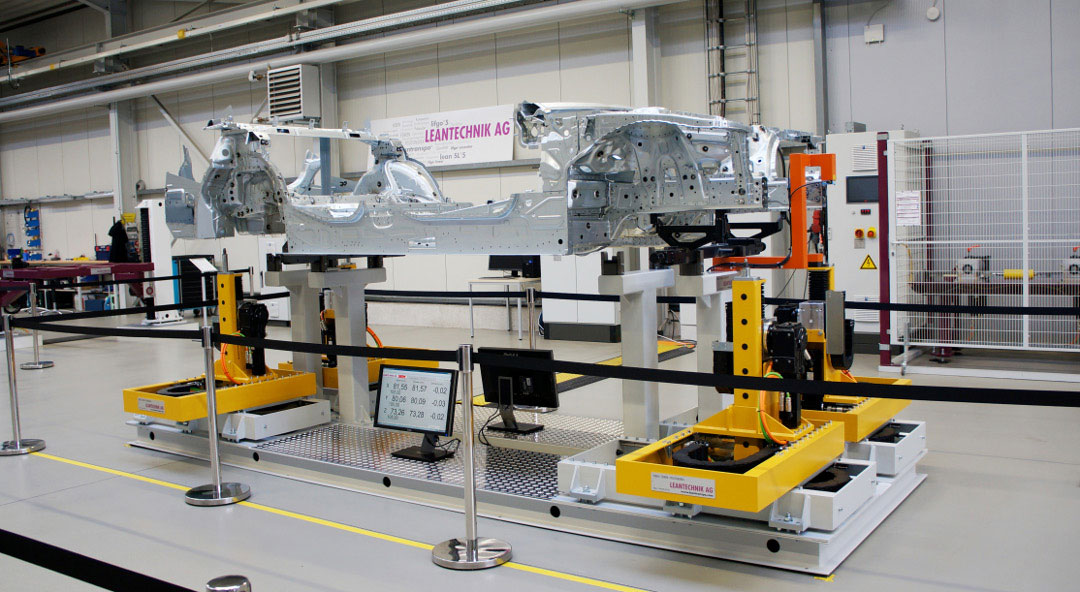

This system was specifically developed for the automotive industry due to industry demands. All renowned automotive manufacturers are under pressure to produce a variety of models, but in smaller production runs. To meet these industry demands, production must be flexible and efficient. One option is to produce several automobile models on a production line. Consequently, you need a “Positioning System” that has been designed for such applications. Our “Three Axis Positioning System” (DAP) has the flexibility to adapt to the various types of chassis and the flexibility to transport through the production line as parts are installed.

High Precision Positioning

Primary point of the DAP is our Gear Rack Drives, in that rotatory movement is transferred to linear movement. Our lifgo® Gear Rack Drives have precise roller bearings which provide exact positioning and are outstanding for high lifting speeds and the delivery of high transverse forces. There are four model variations in three sizes available and in addition the lifgo® 5.4 is for extreme weight situations.

Perfectly positioned for every automobile model.

Through the combination and synchronization of two or four lifgo® Drives powered by an electrical motor, the positioning system has the ability to move in different directions without extensive programming or assembly. Therefore, synchronized vertical and horizontal lift movements are achievable without difficulties. On the X-axis a lift from 500 mm (19.68 inches), the Y axis from 250 mm (9.84 inches) and on the Z-axis from 350 mm (13.78 inches) are possible. The repeatability lies between +/- 0.02 and +/- 0.01 mm. The lifting force is 3,500 N.

The positioning points operate independently from each other. They capture each ends of a chassis with support from take up points and are held with expanding grips. A controller jointly regulates each automobile model with essential spacing between the lifting points, lifts parts for the welding robot and manages other production processes at ideal working heights.

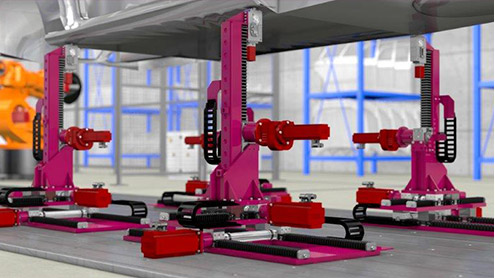

Flexible Engineering & Production floor planning

DAP (Three Axis Positioning) System offers the user a flexible production floorplan in which the positioning points of each chassis dimension can be automatically orientated. In this respect, LEANTECHNIK is a superior supplier in the production of multi-dimensional chassis.

For automobile assembly, we can offer our Lift & Lower Conveyor System with an additional Lifting System. It positions chassis for continuous operations with speed and precision.

They are prepared to assist with design and development recommendations of cutting-edge solutions that meet your demands and requirements.

Check out our leantranspo® projects and find further information in our full catalogue.

You want to know more about our Three-Axis-Positioning-System (DAP)?!

Our sales team will be happy to advise you!

Our field service representatives are available anytime for a non-binding consultation at your facility. To contact your local representative, check who is responsible for your area.

While our product development and design departments are located at our Oberhausen location, our field service representatives are available to assist you anywhere in the US.

Headquarters:

![]() USA

USA

LEANTECHNIK LP

2220 Northmont Parkway,

Suite 250

DULUTH GA 30096

UNITED STATES OF AMERICA

E-Mail: info@leantechnik.us

Phone: +1 770 295 2286

Web: www.leantechnik.us

![]() USA – Michigan, Indiana, Illinois

USA – Michigan, Indiana, Illinois

Morrell Group, Inc.

3333 Bald Mountain Road

Auburn Hills, MI 48326

UNITED STATES OF AMERICA

E-Mail: sstearn@morrellinc.com

Phone: +1 248 373 1600

Web: www.morrell-group.com

![]() USA – Ohio, Kentucky

USA – Ohio, Kentucky

Hydrotech, Inc.

10052 Commerce Park Drive

Cincinnati, OH 45246-1388

UNITED STATES OF AMERICA

E-Mail:dschaefer@hydrotech.com

Phone: +15138817000

Web: www.hydrotech.com

leantranspo® – Cutting Edge Solution

from the House of LEANTECHNIK

The development and construction of an individual leantranspo®-system integrates Gear Rack Drives – lifgo® and lean SL®, with parts, motors and steel frame structure. Individual leantranspo®-systems can be created for the most discriminate lifting applications.

leantranspo® is significant in the development and manufacture of parts and production systems.

• Lifting Tables and Lifting Columns

• Press Transfer Lines

• Pick and Place Systems

• Two and Three Axis Portals and Positioning Systems

• Lift & Lower Conveyor Systems

Benefit from our experienced engineering team. They are prepared to assist with design and development recommendations of cutting-edge solutions that meet your demands and requirements.