We take you to the

NEXT LEVEL!

With Lifting Tables from LEANTECHNIK

High Speed

Tight Operating Parameters

Low Maintenance

Highest Precision

Simple Installation

Lifting tables for automotive chassis assemble are unreliable. A good example is a motionless lifting station. The chassis is delivered on a high-speed conveyor and lifts it into a stationary position. A robot pulls and installs various parts throughout the production process.

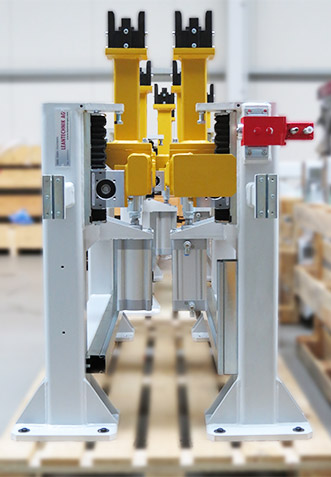

LEANTECHNIK has been a partner with the automobile industry for more than 15 years and is trusted by divisions within. High precision and efficient lifting tables / lifting systems are required, which allow robots to work at optimal levels. The lifting table pictured was built with two double lifting columns and fitted with lifgo linear Gear Rack Drives. And, the vertical lift of 125 cm (49.21 inches) with the exact positioning of 0.01 mm (0.0003937 inches) is perfect to meet the high standards of the automotive industry. The double lifting table can handle high capacity loads with superb repeatability which are important factors in automotive production.

They are prepared to assist with design and development recommendations of cutting-edge solutions that meet your demands and requirements.

Check out our leantranspo® projects and find further information in our full catalogue.

You want to know more about our Lifting Tables?!

Our sales team will be happy to advise you!

Our field service representatives are available anytime for a non-binding consultation at your facility. To contact your local representative, check who is responsible for your area.

While our product development and design departments are located at our Oberhausen location, our field service representatives are available to assist you anywhere in the US.

Headquarters:

![]() USA

USA

LEANTECHNIK LP

2220 Northmont Parkway,

Suite 250

DULUTH GA 30096

UNITED STATES OF AMERICA

E-Mail: info@leantechnik.us

Phone: +1 770 295 2286

Web: www.leantechnik.us

![]() USA – Michigan, Indiana, Illinois

USA – Michigan, Indiana, Illinois

Morrell Group, Inc.

3333 Bald Mountain Road

Auburn Hills, MI 48326

UNITED STATES OF AMERICA

E-Mail: sstearn@morrellinc.com

Phone: +1 248 373 1600

Web: www.morrell-group.com

![]() USA – Ohio, Kentucky

USA – Ohio, Kentucky

Hydrotech, Inc.

10052 Commerce Park Drive

Cincinnati, OH 45246-1388

UNITED STATES OF AMERICA

E-Mail:dschaefer@hydrotech.com

Phone: +15138817000

Web: www.hydrotech.com

leantranspo® – Cutting Edge Solution

from the House of LEANTECHNIK

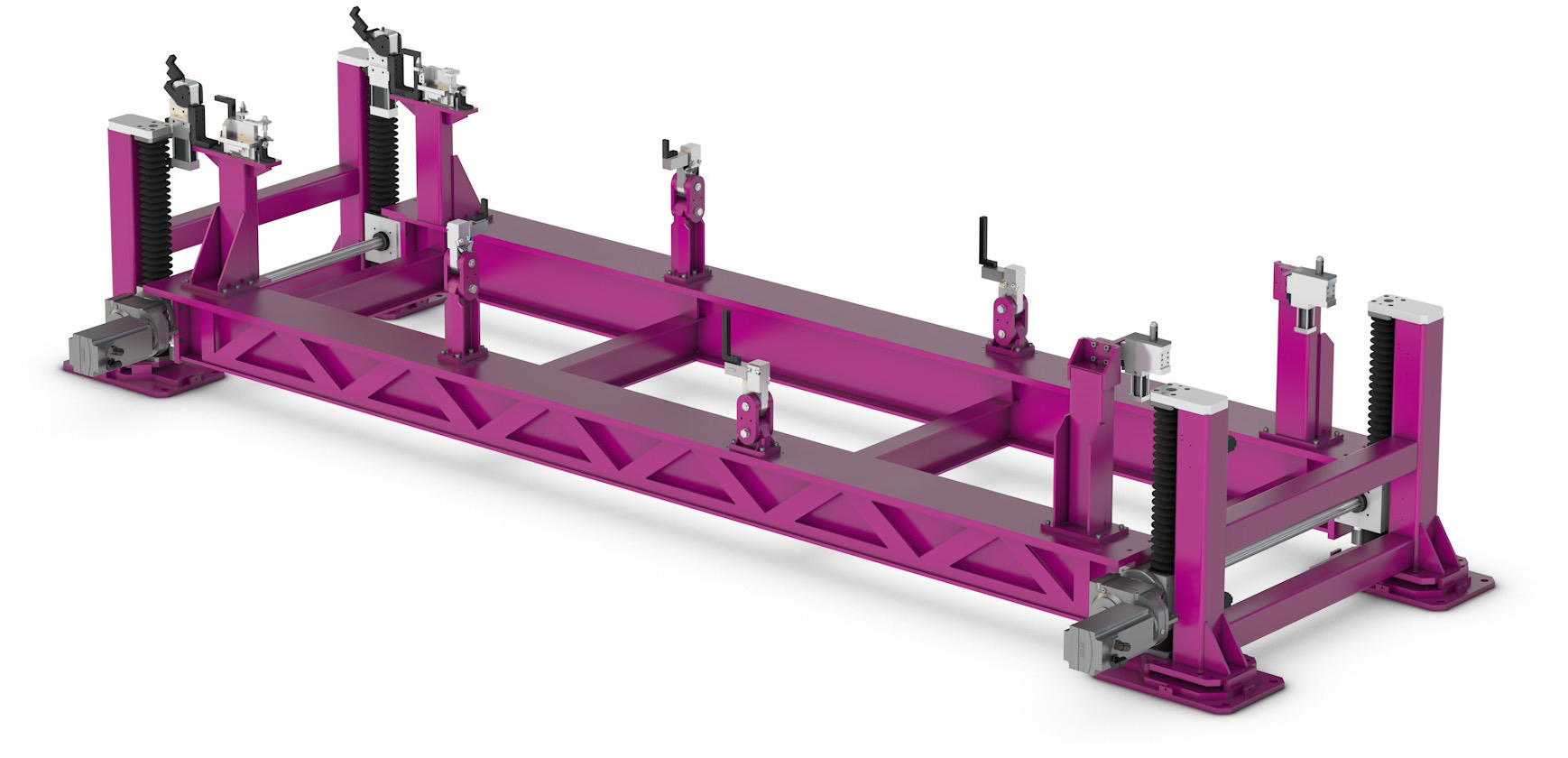

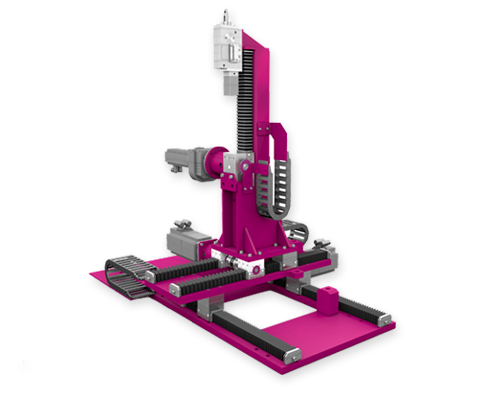

The development and construction of an individual leantranspo®-system integrates Gear Rack Drives – lifgo® and lean SL®, with parts, motors and steel frame structure. Individual leantranspo®-systems can be created for the most discriminate lifting applications.

leantranspo® is significant in the development and manufacture of parts and production systems.

• Lifting Tables and Lifting Columns

• Press Transfer Lines

• Pick and Place Systems

• Two and Three Axis Portals and Positioning Systems

• Lift & Lower Conveyor Systems

Benefit from our experienced engineering team. They are prepared to assist with design and development recommendations of cutting-edge solutions that meet your demands and requirements.